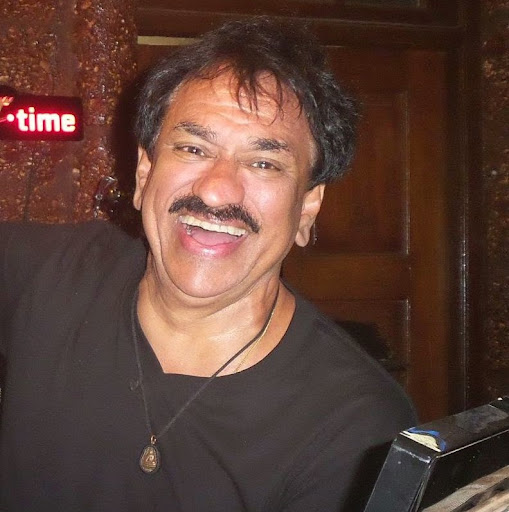

Natraj C Iyer

age ~70

from Lexington, SC

- Also known as:

-

- Natraj N Iyer

- Natrij C Iyer

- Phone and address:

-

117 Turnberry Ln, Lexington, SC 29072

8039517328

Natraj Iyer Phones & Addresses

- 117 Turnberry Ln, Lexington, SC 29072 • 8039517328

- Simpsonville, SC

- Columbia, SC

- West Mifflin, PA

- 117 Turnberry Ln, Lexington, SC 29072 • 8034796920

Work

-

Position:Executive, Administrative, and Managerial Occupations

Education

-

Degree:High school graduate or higher

Resumes

Natraj Iyer

view sourceLocation:

United States

Us Patents

-

Method For Making Vacuum Interrupter Contacts By Spray Deposition

view source -

US Patent:47235896, Feb 9, 1988

-

Filed:May 19, 1986

-

Appl. No.:6/864611

-

Inventors:Natraj C. Iyer - Monroeville PA

Alan T. Male - Murrysville PA -

Assignee:Westinghouse Electric Corp. - Pittsburgh PA

-

International Classification:B22D 2300

-

US Classification:164 46

-

Abstract:A low pressure plasma or laser spray metal deposition process for the manufacture of a vacuum interrupter contact with a tailored composition gradient through the thickness of the contact.

-

Vacuum Circuit Interrupter Contacts And Shields

view source -

US Patent:51209187, Jun 9, 1992

-

Filed:Nov 19, 1990

-

Appl. No.:7/615109

-

Inventors:Robert L. Thomas - Horseheads NY

Natraj C. Iyer - Columbia SC

Allan J. Bamford - late of Horseheads NY -

Assignee:Westinghouse Electric Corp. - Pittsburgh PA

-

International Classification:H01H 3366

-

US Classification:200144B

-

Abstract:Copper-chromium contacts and copper-ferrous material shields are used in vacuum circuit interrupters. The copper chromium contacts include a specific copper-iron non-abutting section, and an abutting layer preferably of copper-chromium with a layer thickness that constitutes about 50% of the total thickness of the contact which constitutes the abutting section of the contact structure. The shield for the contacts, are preferably formed of copper-ferrous material and "X" in which 1%-50% is ferrous material, and "X"=chromium 0% to 30% and ferrous material plus "X" is less than 60% of the total shield. The contacts and shields are formed by a powder metallurgical procedure.

-

Shunt Attachment And Method For Interfacing Current Collection Systems

view source -

US Patent:51686201, Dec 8, 1992

-

Filed:Nov 15, 1990

-

Appl. No.:7/614796

-

Inventors:Paul E. Denney - State College PA

Natraj C. Iyer - Columbia SC

William F. Hannan - Monroeville Boro PA -

Assignee:Westinghouse Electric Corp. - Pittsburgh PA

-

International Classification:H01R 4304

-

US Classification:29597

-

Abstract:A composite brush to shunt attachment wherein a volatile component of a composite but mostly metallic brush, used for current collection purposes, does not upon welding or brazing, adversely affect the formation of the interfacial bond with a conductive shunt which carries the current from the zone of the brush. The brush to shunt attachment for a brush material of copper-graphite composite and a shunt of copper, or substituting silver for copper as an alternative, is made through a hot isostatic pressing (HIP). The HIP process includes applying high pressure and temperature simultaneously at the brush to shunt interface, after it has been isolated or canned in a metal casing in which the air adjacent to the interface has been evacuated and the interfacial area has been sealed before the application of pressure and temperature.

-

Vacuum Circuit Interrupter Contacts Containing Chromium Dispersions

view source -

US Patent:47662743, Aug 23, 1988

-

Filed:Jan 25, 1988

-

Appl. No.:7/147420

-

Inventors:Natraj C. Iyer - Monroeville PA

Alan T. Male - Murrysville Borough PA

Sidney J. Cherry - Elmira NY

Robert E. Gainer - Monroeville Boro. PA -

Assignee:Westinghouse Electric Corp. - Pittsburgh PA

-

International Classification:H01H 3366

-

US Classification:200144B

-

Abstract:A powdered metallurgical procedure for forming chromium copper contacts used in vacuum circuit interrupters, in which prealloyed powder formed by mixing to copper, chromium of between two to thirty-seven weight percent is rapidly solidified after melting at about 1100. degree. C. to 1500. degree. C. This powder may be blended with additional chromium of between 12 to 50 weight percent with a maximum of fifty-five weight percent of chromium in the final contact structure. This blended mixture may then be either (i) cold pressed at 100,000 psig. and vacuum sintered at 800. degree. to 1400. degree. C. ; or (ii) be subjected to hot isostatic pressure of 10,000 to 30,000 psig. at between 700. degree. C. to 1080. degree. C. ; or (iii) containing the blended copper-chromium powder and the additional chromium powder into an evacuated can and hot extruding the can between 400. degree. C. to 900. degree. C. , to form the contacts.

-

Method Of Making Dimensionally Reproducible Compacts

view source -

US Patent:49098411, Mar 20, 1990

-

Filed:Jun 30, 1989

-

Appl. No.:7/374330

-

Inventors:Natraj C. Iyer - Monroeville PA

Alan T. Male - Murrysville Boro PA

William R. Lovic - New Kensington PA -

Assignee:Westinghouse Electric Corp. - Pittsburgh PA

-

International Classification:C22C 2912

-

US Classification:75233

-

Abstract:A process of hot pressing of materials to form articles or compacts is characterized by the steps: (A) providing a compactable particulate mixture; (B) uniaxially pressing the particles without heating to provide article or compact (22); (C) placing at least one article or compact (22) in an open pan (31) having an insertable frame (32) with edge surfaces (34) that are not significantly pressure deformable, where the inside side surfaces of the frame are parallel to the central axis B--B of the open pan, and where each article or compact is surrounded by fine particles of a separating material; (D) evacuating air from the container and sealing the articles or compacts inside the container by means of top lid (36); (E) hot pressing the compacts at a pressure from 352. 5 kg/cm. sup. 2 to 3,172 kg/cm. sup. 2 to provide simultaneous hot pressing and densification of the articles or compacts; (F) gradually cooling and releasing the pressure; and, (G) separating the articles or compacts from the container, where there is no heating of the compacts in the process before step (E).

-

Hot Isostatic Pressing Of High Performance Electrical Components

view source -

US Patent:48102890, Mar 7, 1989

-

Filed:Apr 4, 1988

-

Appl. No.:7/177274

-

Inventors:Norman S. Hoyer - Mt. Lebanon PA

Natraj C. Iyer - Monroeville PA -

Assignee:Westinghouse Electric Corp. - Pittsburgh PA

-

International Classification:C22C 2912

-

US Classification:75232

-

Abstract:A process of hot isostatic pressing of powders to form electrical contacts is characterized by the steps: (A) mixing powders, 1 in the Drawing, from metal containing powder or metal containing powder plus carbon powder, where at least one of Ag and Cu is present, (B) thermal cleaning treatment of the powder, 2 in the Drawing, (C) granulating the thermally treated powder, 3 in the Drawing, (D) uniaxially pressing the powders without heating, 5 in the Drawing, to provide a compact, (E) placing at least one compact in a pressure-transmitting, pressure-deformable container, 6 in the Drawing, and surrounding each compact with fine particles of a separating material, (F) evacuating air from the container, 7 in the Drawing, (G) sealing the compacts inside the container, 8 in the Drawing, (H) hot isostatic pressing, 9 in the Drawing, the compacts through the pressure transmitting material at a pressure from 352 kg/cm. sup. 2 to 2,115 kg/cm. sup. 2 and a temperature from 0. 5. degree. C. to 100. degree. C.

-

Method Of Treating A Coating On A Reactor Coolant Pump Sealing Surface

view source -

US Patent:49784870, Dec 18, 1990

-

Filed:Jan 13, 1989

-

Appl. No.:7/296654

-

Inventors:Elmer E. Eiffler - Glenshaw PA

Natraj C. Iyer - Monroeville PA

Alan T. Male - Murrysville PA

David J. Boes - Monroeville PA -

Assignee:Westinghouse Electric Corp. - Pittsburgh PA

-

International Classification:B05D 312

-

US Classification:264 60

-

Abstract:An annular chromium carbide coating on an annular sealing surface of a stainless steel sealing assembly component for use in a nuclear reactor coolant pump, is treated by encasing at least the chromium carbide coating on the stainless steel sealing surface by applying a metallic cover thereover, evacuating the atmosphere between the cover and the coating on the sealing surface, hot isostatic pressing the stainless steel sealing assembly component and the chromium carbide coating thereon encased by the cover, cooling the sealing assembly component and the coating thereon encased by the cover, and after cooling thereof removing the cover from the coating. The result is a chromium carbide coating on the sealing component substrate densified substantially to its full theoretical density (greater than 99%) and metallurgically bonded by the hot isostatic pressing to the substrate exterior surface.

-

Cryogenic Conductor

view source -

US Patent:49279858, May 22, 1990

-

Filed:Aug 12, 1988

-

Appl. No.:7/231040

-

Inventors:Natraj C. Iyer - Monroeville PA

Walter J. Carr - Wilkins Twp., Allegheny County PA

Alan T. Male - Murrysville PA -

Assignee:Westinghouse Electric Corp. - Pittsburgh PA

-

International Classification:H01B 1200

-

US Classification:1741251

-

Abstract:A composite hyperconductor for use at cryogenic temperatures and particularly well suited for AC applications employs at least one filament of conductor having an extremely low electrical resistance at cryogenic temperatures, a strengthening matrix surrounding the conductor, and a barrier for electrically insulating the conductor from the matrix while providing for efficient heat transfer therebetween and/or serving as a diffusion barrier to prevent contamination of the high purity conductor during processing. The preferred composite hyperconductor for space applications comprises an ultra high purity aluminum conducting filament, a aluminum alloy matrix and a boron nitride barrier.

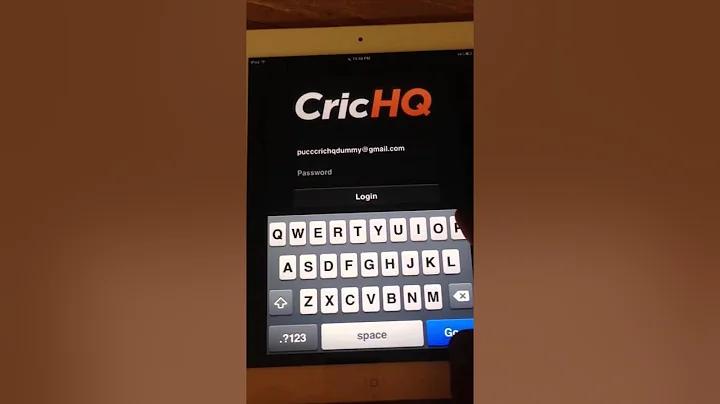

Youtube

Natraj Iyer

view source

Natraj Iyer

view source

Iyer Lavanya Natraj

view source

Natraj Iyer

view source

Anand Natraj Iyer

view source

Anand Natraj Iyer

view source...

Natraj Iyer

view sourceGoogleplus

Natraj Iyer

Natraj Iyer

Natraj Iyer

Get Report for Natraj C Iyer from Lexington, SC, age ~70