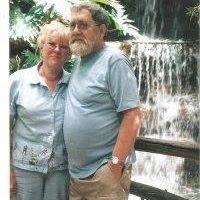

Judy P Easterling

age ~75

from Angleton, TX

- Also known as:

-

- Judy Pauline Easterling

- Phone and address:

-

133 Trail Ride Rd, Angleton, TX 77515

9798495406

Judy Easterling Phones & Addresses

- 133 Trail Ride Rd, Angleton, TX 77515 • 9798495406

- Mexia, TX

- Denver, CO

- Clute, TX

- Killeen, TX

Us Patents

-

Apparatus For Treating Particles

view source -

US Patent:20090145355, Jun 11, 2009

-

Filed:Sep 10, 2008

-

Appl. No.:12/207884

-

Inventors:Jay R. Garner - Clute TX, US

Paul R. Meiller - Lake Jackson TX, US

Dominick A. Burlone - Rio Rancho NM, US

R. Merritt Sink - Charlotte NC, US

Judy Easterling - Angleton TX, US -

International Classification:B05C 5/00

-

US Classification:118303

-

Abstract:An apparatus for treating a plurality of particles, such as ammonium sulfate, with a coating, such as a wax, to prevent caking of the particles. The apparatus includes a feed chute, a diffuser and an exit chute. An applicator is mounted adjacent a base of the diffuser for spraying the coating downwardly away from the diffuser into a predefined pattern. The exit chute includes a deflector for intersecting a curtain of particles falling from the diffuser and for redirecting the particles into the predefined pattern of the coating. A heating element is mounted to the deflector for maintaining a predetermined temperature of the deflector thereby preventing accumulation of the coating on the deflector.

-

Method Of Treating Particles

view source -

US Patent:20070212482, Sep 13, 2007

-

Filed:Mar 10, 2006

-

Appl. No.:11/276701

-

Inventors:James Nevin - Lake Worth FL, US

Jay Garner - Clute TX, US

Dominick Burlone - Lake Jackson TX, US

Paul Meiller - Lake Jackson TX, US

R. Sink - Lake Jackson TX, US

Judy Easterling - Angleton TX, US

Erik Mayer - Prairieville LA, US -

International Classification:B05D 7/00

B05D 1/02 -

US Classification:427212000, 427421100

-

Abstract:A method of treating granules with a coating utilizing an apparatus having a feed chute, a diffuser mounted adjacent the feed chute, a spray nozzle, and an exit chute having a deflector disposed below the diffuser and spray nozzle. The method comprises the steps of: feeding the granules into the feed chute; intersecting the granules with an angled wall of the diffuser to create a curtain of granules falling about a base of the diffuser; spraying the coating from the spray nozzle downwardly away from the diffuser toward the deflector of the exit chute in a predetermined conical pattern; and intersecting the granules with the deflector to redirect the granules into the conical pattern of the coating for treating each of the granules with the coating. The subject invention provides a method of efficiently treating a large throughput of granules with an appropriate amount of coating.

Resumes

Judy Easterling

view source

Judy Easterling

view source

Judy Easterling Barker Cn

view sourceFriends:

Grover Barker, Gloria Psimer, Ronnie Easterling, Jim Easterling, Kevin Gilbert

Judy Easterling Barker Conn

Judy Easterling

view sourceFriends:

Tracey Sheets, Sandy Smith, Oonhi Akin Dunn, Larry Easterling, Brenda Dalton

Judy Easterling New Orle...

view sourceGoogleplus

Judy Easterling

Flickr

Classmates

Judy Conn (Easterling)

view sourceSchools:

Olive Hill High School Olive Hill KY 1965-1969

Community:

Linda Qualls, Verla Gates

Biography:

I married Dallis Barker shortly after graduating and moved to Ashland, Ohio for four...

Raleigh High School, Rale...

view sourceGraduates:

Judy Easterling (1967-1971),

Anita Grahm (1992-1996),

Terry Ashley (1960-1964),

Michael Kennedy (1988-1992),

Joanna Adcock (1989-1993),

Audrey Reagan (1994-1997)

Anita Grahm (1992-1996),

Terry Ashley (1960-1964),

Michael Kennedy (1988-1992),

Joanna Adcock (1989-1993),

Audrey Reagan (1994-1997)

Hope High School, Hope, A...

view sourceGraduates:

Sonya Johnson (1972-1976),

Nicolle Rainwater (1995-1999),

Judy Easterling (1957-1961),

Denyse Breeding (1987-1991)

Nicolle Rainwater (1995-1999),

Judy Easterling (1957-1961),

Denyse Breeding (1987-1991)

Garfield High School, Akr...

view sourceGraduates:

Judy Easterling (1972-1976)

Wolfe County High School,...

view sourceGraduates:

Debra Bryant (1981-1985),

Judith Easterling (1970-1974),

Patricia Vancleve (1965-1969),

Judy Roberts (1964-1968),

Donna Landsaw (1981-1985)

Judith Easterling (1970-1974),

Patricia Vancleve (1965-1969),

Judy Roberts (1964-1968),

Donna Landsaw (1981-1985)

Youtube

Myspace

Get Report for Judy P Easterling from Angleton, TX, age ~75